I want to work with a screen printer. Where do I start?

So you’ve decided to start selling your art in the form of screen printed tshirts. You’ll want to have a general idea of what services you need before starting the journey of hiring the perfect screen printer.

Knowing where to start is the most difficult part. You don’t have to have all of the answers, but there are a lot of things to begin considering. Consider your answer to each of the questions below. These questions will help you think about all the elements that go into finding the perfect printer.

Ask Yourself These Questions:

How many designs do you wish to sell?

What is the minimum number of designs you wish to sell?

How many colors does each design contain?

What is the size range you hope to sell?

Do you prefer to pay a higher cost for a higher quality tshirt?

How many tshirts of each size and design do you wish to have?

How much do you plan to sell each tshirt for?

If you have a 100% to 300% markup per each shirt, what is the maximum you could pay per printed tshirt?

In how many different locations will each design be printed? For example, the front, the back, the tag, the sleeve, etc.

What form are your designs in now? Are they digital? If so, what file format are they in?

Are you familiar with vector file formats?

Will you need help preparing your designs for the printer?

Is Made in the USA a necessity for you?

What should I know about my designs and file formats?

Determine how many different designs style t-s you will start with. Take a look at the format of your designs. Are they simple sketches, are the .jpg photos, are they .ai or .esp? The more you understand about file types, the better, but it’s ok to have little or no understanding. Most screen printers have an individual or a team dedicated to preparing artwork for print. Be prepared for screen printers to require your files in vector format or to charge you a fee for prepping your art files.

Why do file types matter so much?

Screen printing is done in layers. Typically each color of a design is a new layer and uses a new screen. A four-color design would likely use four separate screens, one for each color. The more complex the colors are in your design the more layers or screens would be necessary for taking your design to print. Talented screen printers should be able to use a combination of screen colors to develop various hues. The most easily executed screen print designs are clearly divided by color. Designs with varying shades of multiple colors are more difficult. Screen printing is best for fewer than 6 colors. If you’re interested in printing photo-like designs or designs with an extensive number of colors, you might want to consider different printing methods like DTG or Direct to Garment. You’ll quickly learn which screen printers are willing to take on more complex designs. Keep in mind, screen printing may never look exactly as your image does on a computer. Ask your screen printer to see samples of their work. Ask as many questions are you can and do your best to gain and understanding of the screen printers process. This will help you in preparing your own file types as well as understanding the process that your designs may need to go through in preparation.

Vector Formats-

.ai or .esp. The best type of file for screen printing is a vector format image.

The best way to understand vector formatting is to image that your image is a group of shapes rather than a series of pixels. Vector images are conveyed to computers as a mathematical equation. The equation tells your computer exactly what shapes that your file consists of. Vector images do not lose resolution or quality when resized. That is why they’re best for screen printing. Your printer can use your vector file and change the size to best fit the needs of his equipment. For example, a vector file will treat the border of an image like a solid shape. In contrast, a .jpg file would treat the image like a series of pixels and the border would become pixelated or blurry when the image is made larger. A .jpg is a raster image.

.ai

AI stands for Adobe Illustrator. Anytime you use Adobe Illustrator to create a design or image, you are working with a .ai file format. This is Adobe’s unique file format for vector files. Most printers are very familiar with .ai and will be glad to print those files for you. Keep in mind, you do need Adobe Illustrator to create or edit .ai files.

.eps

EPS is considered a standard vector file format. It is considered the go-to file format for designs that need to be resized. Logo are a great example of image types that are best in the .eps file format. .eps isn’t a suitable file to use on the web but it is the perfect file to share directly with your printer.

Raster Images

– common file types that might be accepted for screen printing but are not ideal .jpg, .gif, .png, .tiff, .psd.

Many screen printers will accept raster images. Raster images consist of pixels or tiny colored squares. They can make up simple images or huge photographs. Raster images are made up of a set number of pixels. When the size of a raster image is changed, the quality suffers. This explains why if you expand the size of a .jpg image, it will become blurry or pixelated. Raster images are great for final web images. In the screen printing process, your screen printer might go through a process to change your raster image formats to vector file formats. This is where charges for “art prep” might come in.

.jpg

JPEG or .jpg files are perhaps the most common file type to those unfamiliar with various file types. JPEG file formats are small and convenient because they take up minimal storage space on computers and memory cards. They allow web pages to load quickly and can save space on a harddrive in comparison to similar file types. JPEGS are not good for print because they lack the quality to convey crisp clean lines to printers. They also do not maintain clarity or quality when resized.

.gif

GIF or .gif images aren’t good for print. GIF’s are used for small file size animation or small files with transparency. You’ve likely seen a .gif of a funny dancing cat or a clip of a tv show. They are good for the web in that they maintain a small file size even with transparency but they do not resize well and do not produce crisp, clear images that are necessary for print.

.png

PNG files are similar to .jpg files but with the benefit of being sized much bigger and have the ability to include transparent elements. PNG’s take up a lot more space than .jpg and explains why you seem for .jpg files than .png files on the web. If your designs are in .png format it is likely that your files will be big enough to easily convert to vector or print ready images.

.tiff

Tiff files are good for print. They are very large file formats that do not change or lose quality when resized. TIFF’s have the ability to support layers of images as well. This is nice for screen printing because printers will break your images down into layers of colors of ink for print. While .tiff is a seemingly ideal file format, printers that are most accustomed to Adobe products might prefer .ai or .psd files.

.psd

PSD file formats are native adobe files that, like .tiff support layers. They are often used for print as they can break down images into said layers and most printers are familiar with Adobe products.. Photoshop is used to create .psd files. If you have the skills to design within and work with Adobe photoshop, you may be able to convert your .psd files to .ai with ease.

How do designs and file types affect the cost of screen printing?

Number of Colors

The more color complexity within your design, the more difficult the design will to break down into screens and the more screens will be required for print. Unless you can fully prepare the design files yourself into color layers, the screenprinter will charge you for this service. Screen printers charge by the screen as well. So consider that the more colors you have, the more screens and the more cost you’ll run into. Another additional cost associated with the number of colors is the mixing of and use of paints. Custom colors are created by custom blended paints. Each color takes time and resources to produce.

Art Preparation

Understanding various file types is the first step in understanding any charges associated with art preparation. Even with the most ideal file types, screen printers may charge for the process of converting those files to screens. Ideally, you’ll be able to provide vector files to your printer in order to avoid any additional costs. When you give a printer a raster image, particularly the most popular .jpg and .png files, you are asking them to break the design down into colors and shapes as they best interpret the design. This process can be time consuming, costly and allows room for error. Understand what file types you are giving to your printer. When I went through the screen printing process, I googled the process of turning .png’s into .ai and was able to convert the files myself. Never underestimate the power of a well executed google-search.

How do I choose the best t-shirt for my project?

If you’re manufacturing your own tshirts, you likely have a very good understanding of the materials involved in creating your tees. Most people, however, choose to source their tshirts from a pre established wholesaler with many years of experience a developed expertise. Its often the more affordable option. I did research on creating my own custom garments and the cost started at a minimum of $20,000, not exactly low startup for a tshirt business. Here are some common fabric types and blends that you’ll find from tshirt suppliers.

Standard Cotton

Cotton tshirts are an affordable frequently used options in screen printing. There are many wholesale cotton tshirt suppliers. Cotton is great for screen printing. The paints used in screen printing attach easily to cotton fibers and make for quality, long lasting prints. The down-side of cotton is that in comparison to it’s blended counterparts, it is not as soft to the touch. Additionally many prefer not to use cotton because of its characteristic of losing its shape or shrinking significantly when washed. When I was first testing screen printing options, the cotton tees looked great but when washed, they shrunk almost 3 full sizes! Consider cotton tshirts when printing tshirts for one time events.

Ring-spun cotton

Ring-spun cotton is a great alternative to regular cotton. Ring-spun refers to the process the cotton is put through when the material is created. The cotton goes through a spinning process that makes the fibers softer and straighter. This results in a much more durable fabric that is also softer than regular cotton. These tshirts will be more expensive than their traditional counterparts but will be worth the upgrade in quality and softness. Also, ring-spun cotton is still more affordably priced that most blended fabrics.

Dual Blend: Cotton & Polyester

For our screen printing needs, we chose a 60% cotton 40% polyester blend fabric. Screen printing paint most easily attaches to cotton fibers. Because the fabric is primarily cotton, screen print designs hold up well when washed. The blend of the two fabrics makes the tshirts feel much softer and thinner than traditional cotton, but they maintain good quality durability with the polyester blend.

Tri Blend: Cotton, Polyester & Rayon

Tri-Blend tshirts are very soft. When you feel a tri blend tshirt in comparison to a 100% cotton tshirt, you’ll immediately recognize the silky soft feel. Tri-blend tshirts are often of very high quality and are likely to have your favorite “feel.” Screen printing paints will bond best with cotton and not as well with polyester and rayon. By choosing a tri-blend fabric, you’ll choose a great feeling product but your screen print design will be more susceptible to fade and deteriorating because it has less cotton to bind to.

How do I choose a t-shirt supplier?

Most screen printers have established relationships with wholesale suppliers. When you meet with a screen printer, they’ll be able to show you the options of tshirt styles, brands and materials that they can source. It’s convenient to use one of the options supplied by your printer and the most used practice. If you prefer to use your own source, most screen printers will be open to your providing your tshirt blanks for your printer to print on. Keep in mind you’ll need to establish a wholesale account with a supplier which can prove to be a long process in itself.

Consider the types of products you’ll want to sell. You’ll want to get a quality product from a business that utilizes fair practices and safe working conditions. Take the time to research the wholesale suppliers and choose both a product you feel good about as well as a company. Here are some of the most popular wholesale tshirt suppliers.

Bella + Canvas

Next Level Apparel

Hanes

Anvil

Royal Apparel

Blank Apparel

Jones T-Shirts

The Deal Rack

Jiffy Shirts

The Adair Group

You can source samples of tshirts from screen printers or from the wholesalers themselves. Understand that screen printers may markup the cost of wholesale tshirts in order to increase their profit margins. This is a normal practice but you’ll be able to tell which printers are charging you “an arm and a leg.”

How should I choose what sizes and how many of each t-shirt to order?

To choose the perfect amount of tees to order, you’ll want to understand order minimums and estimate what you plan to sell. Unless you’re printing tees that have been pre-ordered, this part is tough. The only way to guarantee you aren’t over or under-printing is to presale your tshirts. This is great for one time events but isn’t typically realistic for someone looking to sell their tshirts as part of a brand, on a website or in a retail store. A very general size guide for adult tshirts is 1-2-2-1 for sizes S-M-L-XL. You might want to also consider adding a small ratio of XS and XL to your order. For children’s sizes, the size ratios aren’t as clear. You’ll want to adjust your ratio based on your specific target market. Through trial and error, we learned that our most popular sizes from toddler to age 12 was the largest of toddler sizes.

Also consider the turn-around time it will take to receive your final product. Typically, orders will take from 2 to 4 weeks. So you’ll want to have sufficient supply to get you to your next order but it’s best to underestimate and sell out of inventory than to sit on excess stock. Start small.

Screen print minimums often vary from as few as 12 to as many as 100. I choose a screen printer with a minimum order quantity of 36 tshirts per design. A good quantity guide for adult tshirts and a 36 shirt minimum would be 6-12-12-6 or 6 Small, 12 Meduim, 12 Large, and 6 XLarge. Personally, I’d throw in 2 XS and 2 XXL’s for good measure.

What information will the screen printer need?

In order to even get a quote from a screen printer, you’ll need to have your printing needs organized so you can clearly convey your needs. Learning how to organize your orders early on will save you from future headaches and breakdown in communication. Likely, the screen printer will tell you exactly what they need from you but here is what you should expect. Be prepared to provide:

-design files

-tshirt brand, style and color choices

-paint color choices, or say “printer’s choice”

-exact size of your designs

-location of where your designs will be printed on the tshirts

-desired quantities of each style and size

-style of print, do you want a bold stark colors or a slightly faded look

If you included all of these things you’ll be well on your way to clear communication with your printer. The more details you can provide and the more specific you can be, the more likely you will be to receive a product that is exactly what you had in mind. Most issues I’ve run into with screen printers have been due to a lack of clear communication.

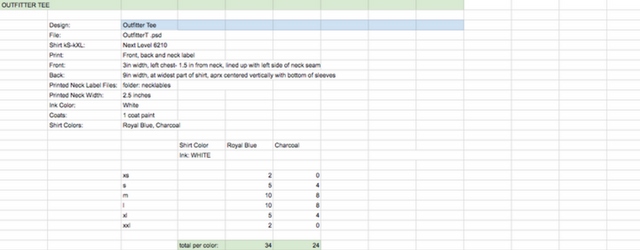

For each design, I list all the information I can about how I want the design printed. This is an example of the first draft I would send to a printer. I would ask if the information here is presented in a way that works well for the printer and if there is anything I can do to improve the presentation. It’s not perfect, but its a good place to start.

How many errors or misprints in considered acceptable?

There will be errors in your first run of screenprinting and likely with every order. It’s best to talk about misprints with your printer before you pay for their services. Understand your printers policies for the percentage of acceptable misprints and errors. Keep in mind, errors that are caused by a lapse in communication can often be the liability of you the client, rather than the printer. The more information you can provide, in writing, the better. The industry standard for misprinted shirts is about 3%. Some printers, however, will protect themselves by saying they may have as many of 10% misprinted tees. I’ve had good and bad experiences with how printers respond to errors. Your first run of prints will be a great test to see exactly how your printer responds to errors and miscommunication. Our first printer gave us over 50% of misprinted tees! The tees themselves were the wrong color and the printing was sloppy and not of sellable quality. They responded with great intentions but even the reprints they sent were significantly misprinted. We went with a new printer who is quick to correct mistakes and is much easier to communicate with. Sometimes trial and error is the only way!